Our “roll up the sleeves and get to work” attitude

Our company’s ingenuity got its start at Bob Liland’s kitchen table when he taught himself the urethane business.

Bob isn’t one to take “no” for an answer. Over the years, he created our company’s “yes we can” attitude by continually innovating.

Today, this spirit is part and parcel of everything we do:

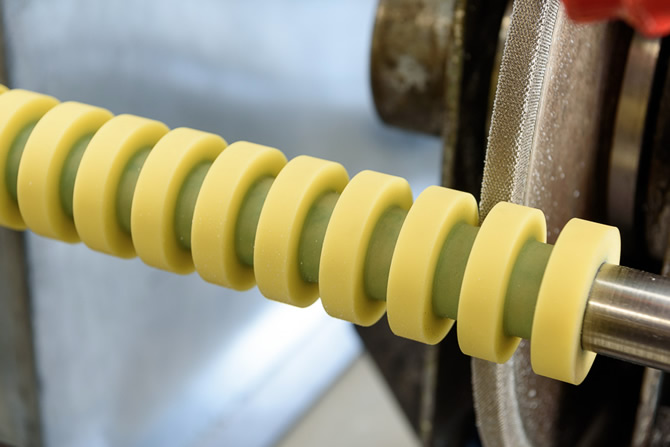

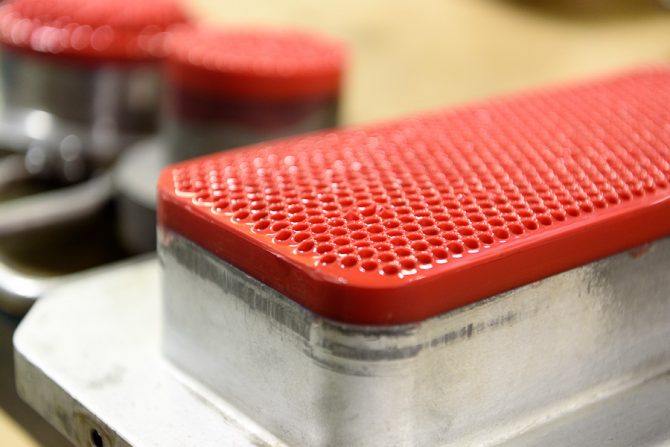

- Recommending design changes to improve urethane part performance or production time

- Putting our heads together to solve tough challenges

- Finding ways to innovate processes to help keep your costs low

- Building a state-of-art machine shop in order to eliminate costly outsourcing

- Creating all our own molds in-house

If you have a manufacturing or application challenge and are looking for original ideas and a “yes we can” attitude, be sure to look through our Challenges Solved page – and then contact us.

Our entire team, from sales to the production floor, is ready and willing to roll up our sleeves and get to work for you.

Learn More

UI Helps Engineering Company Reduce Costs for Urethane Parts

Steps included testing new formulations, eliminating process steps, and improving part quality.

Challenges Solved

We've built a reputation for tackling tough manufacturing and industrial challenges using urethane, silicone and plastics.