Precision Machining of Cores, Inserts, and Hubs

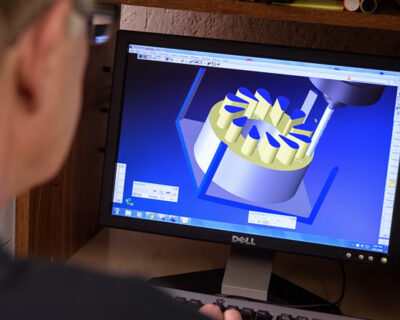

With our state-of-the-art CNC machine shop and 3D printing capabilities, Urethane Innovators can handle all your aluminum, steel, and composite machining needs while meeting your tight tolerance requirements.

Working in conjunction with our engineering department, our machine shop can take your CAD drawings and produce cores, inserts, hubs, and other components in a matter of hours versus days or weeks for outsourced parts.

We can accomplish exterior finishes such as polished, fine and rough grind, tooled, and anti-slip to produce optimal results for your finished product.

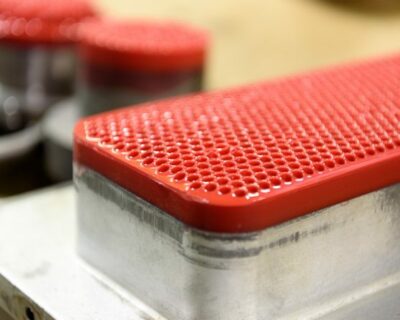

In-House Mold Making = Reduced Production Time and Improved Quality

Outsourcing the manufacture of molds can delay projects and increase costs. To eliminate both and improve quality, we manufacture all our open cast and compression molds in our CNC machine shop to your exact tolerances.

We machine molds from various types and grades of metal, including aluminum and steel. If creating a metal mold for a very large part proves cost prohibitive, we can build “soft” molds – which are urethane molds cast inside a metal outer mold – saving weight, money, and production time.

For repeat orders and/or multiple molds, Urethane Innovators offers mold storage as a complimentary, value-added service.