We solve your tough application challenges

At first glance, rollers, covered bearings, and no-crush wheels look pretty basic. If you’ve looked through other urethane product providers, it appears all of us do the same type of work.

Urethane Innovators, however, is different – and the difference begins with our name. Since 1977, we’ve built a reputation for tackling tough manufacturing and industrial challenges using urethane, silicone, and plastics – and we’ve taken this expertise to a whole new level of innovation and problem-solving.

Whether it’s working with you to enhance the design of new products or producing high volumes under tight deadlines, we have the know-how and ingenuity to solve your most pressing application challenge.

Retrofit drain seal

Challenge: Design a series of retrofit drain seals that self-adjust to pipe size.

Solution: In addition to being self-adjusting, the drain seals needed to maintain drain flow-rate codes and provide leak-proof protection. According to the customer, this had never been done before but could UI create something? Oh, and by the way, “we’re six months behind schedule . . . .”

Through a determined company-wide effort, and using our 3D rapid prototyping capabilities, UI and the customer’s engineering team fabricated multiple prototypes and proof-of-concept parts in weeks, allowing the customer to perform in-house flow-rate, leak and functional testing in record time. UI’s prompt and focused efforts helped the customer get back on schedule, present actual product at their annual industry trade show, and be first-to-market.

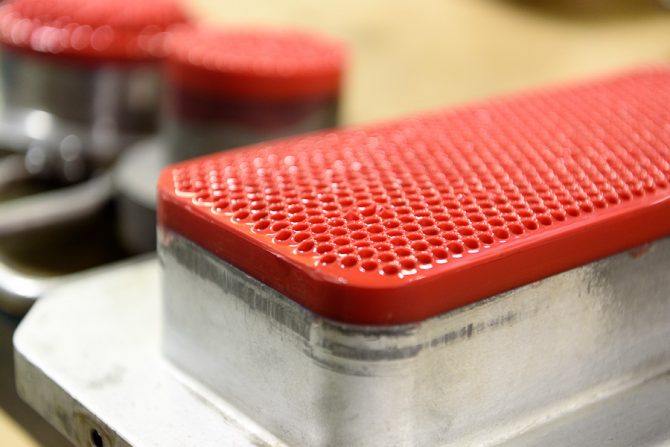

Urethane covers for steel heads

Challenge: Provide urethane covers, with precise hole placement, for industrial steel parts.

Solution: Used in an assembly process by a global industrial equipment manufacturer, these parts feature a urethane cover that acts as a cushion to provide impact and abrasion resistance during the manufacturing process. The critical part of the urethane production process is precisely matching the holes in the urethane with the holes in the steel head.

Dual roller with cut out

Challenge: Create a unique dual roller with aluminum core for a material handling application.

Solution: Working with the customer, UI created the aluminum core in-house and then covered it. Due to our process and expertise, we reduced production time significantly as well as material costs because we didn’t have to grind through the middle of the urethane to achieve the cut out.

Precision mini-rollers

Challenge: Create very small, high precision, high tolerance rollers for a material handling application.

Solution: Working with the customer, UI developed the molds for the aluminum cores and the outer urethane covers in-house. The natural urethane roller on the left is 10” long. The blue roller, at 3” long, was especially challenging due to the tight tolerances.

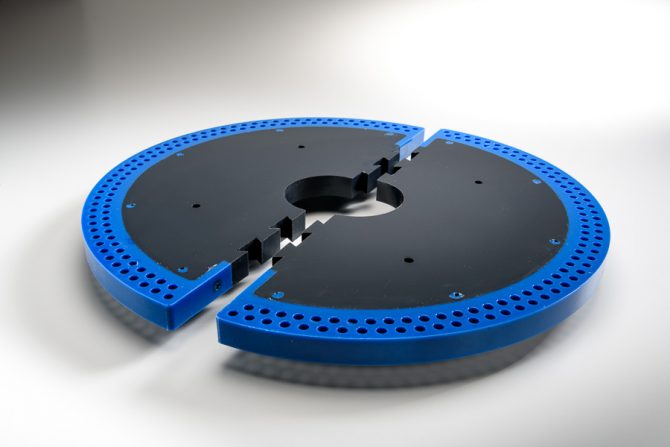

Urethane plate for industrial machine

Challenge: Create a two-piece replacement wheel to facilitate quick change.

Solution: The customer wanted to change the wheel out as quickly as possible without having to remove the shaft and all the other wheels. The inner plate was molded using 70D urethane; for the outer rim we used 60A urethane and then cast it around the black. The holes provide cushion similar to a no-crush wheel. The pieces easily snap together on the machine shaft without having to remove the shaft – saving the customer significant downtime. Two plates bolt together on the shaft (note the four bolt holes). This project is an example of how UI worked with the customer to develop a prototype based on a concept; we then mass-produced the part.

“Puzzle piece” belt for industrial machine

Challenge: Create a belt that snaps together to hold an idler wheel in place on a machine.

Solution: Creating this belt took some ingenuity due to the seam, which needed to quickly and easily slide together, and the tight tolerance of the belt. The part was created with non-silicone mold release urethane; UI consulted with the client on the concept drawings as well as the type of adhesive to use in the seam once the belt was snapped into place.

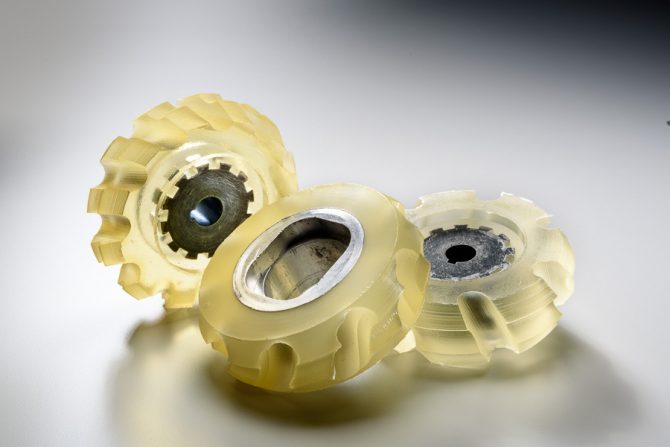

Urethane wheel with hardened inner hub

Challenge: Create a lightweight wheel to withstand the day-to-day rigors of a softball pitching machine.

Solution: This urethane wheel features three layers and two durometers of urethane: an aluminum core, a hard urethane inner hub (yellow), and a softer outer hub. The aluminum core, created in-house by UI, provides stability, while the inner yellow hub helps reduce weight and material costs (in fact, it’s less expensive to make the urethane hub in the U.S. than it is to make a steel hub in China). The outer hub is machine ground with a cast edge surface.

Urethane cast wheels for food application

Challenge: Create FDA approvable urethane cast wheels to exacting tolerances and without bubbles in the nooks and crannies.

Solution: The customer needed to create various wheel shapes, with differing cores, to very tight tolerances using FDA approvable urethane. For FDA applications, bubbles in the urethane mean the part has to be stripped and remade, as bubbles attract bacteria. By working with UI, the customer continues to have parts made to specification while keeping manufacturing costs in check.

Urethane wheel for CNC machine

Challenge: Create a transparent urethane wheel.

Solution: Using the right additives at precise times during the mixing process is the secret to creating transparent urethane. Made of a medium-soft urethane, this wheel is used to hold down and help move wood through a CNC machine. The same wheel is made in different durometers and colors for use in specific locations on the machine.

Flexible pull roll

Challenge: Create a pull roll to drive various thicknesses of cardboard through a machine without creasing it.

Solution: Due to the various types of cardboard running through a machine, the customer was spending a lot of time stopping the machine and fine-tuning it each time the line changed. To solve this problem, UI created an inside out no crush wheel. The wheel features two castings of urethane: the harder inner wheel and the softer outer wheel. The wheel is split and both halves bolt together. Instead of creating openings in the urethane, we added fingers – which grab the various thicknesses of cardboard without having to stop the machine or creasing the cardboard.

Parts for blister pack machine

Challenge: Create two deceptively simple yet challenging FDA approvable urethane pieces for use in the pharmaceutical industry.

Solution: Both pieces are based on proprietary designs provided by the customer. Created from FDA approvable urethane, the main challenge with the red flap on the left was determining how to cast the rolled edge and then ease it out of the mold without catching bubbles or tearing it.

The hard urethane wheel to the right is also deceptive in its simplicity. The inside features intricate shapes, which we’re not allowed to photograph; the outside is tapered through grinding.

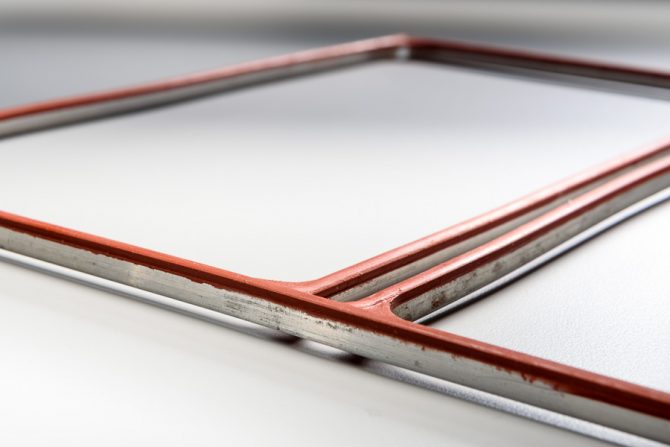

Silicone coated frame

Challenge: Create an FDA approvable silicone covered wire frame without welding.

Solution: To create this frame, UI cuts the client supplied aluminum and assembles the pieces in the compression mold. The high-consistency silicone is compression molded over the metal strips, creating a flexible, but sturdy frame.

Precision covered bearings

Challenge: Create coverings for multiple bearings to precise OD to increase load bearing stability.

Solution: The green covered bearing is an example of two bearings covered by a very hard durometer urethane; the red is an example of one bearing covered with equally hard urethane. Each part has been ground to a precise outer diameter. UI can also add a shape or profile to the OD if required.

Concave radius wheel

Challenge: Create a soft wheel with concave radius for textile application.

Solution: Used on machine to stretch fabric for the textile industry, this part needed to be very soft and very clean with absolutely no rough edges. In addition to the urethane cover, UI created the aluminum core at our in-house CNC machine shop.

Boltable wheel for high load application

Challenge: Develop a part that allows removal of a roller without having to take the machine apart.

Solution: This part looks tiny but it plays a huge role in saving the customer significant machine down time. The customer initially came to Bob Liland with their challenge: how to remove a roller without taking the machine apart. Working with customer, Bob then developed the concept. Made from 70D urethane, the two halves of the wheel bolt together on the roller.

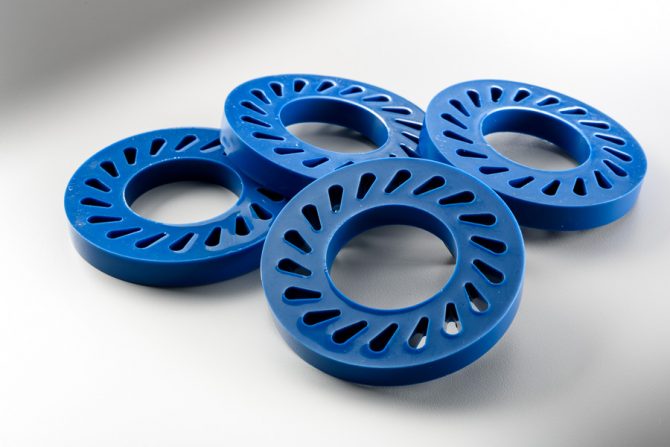

No crush capper disk

Challenge: Create zero crush wheels for an industrial bottling application.

Solution: Used for screwing tops on bottles, these capper disks were created from very soft urethane. The challenge, however, was designing the tooling to include a full fillet radius. UI worked with the customer to enhance the CAD drawing in order to save on tooling and production costs. UI then created the tooling in-house and manufactures these parts on a continual basis.

Automotive dunnage

Challenge: Create tooling and parts for a dunnage application

Solution: UI worked with the customer to improve the design that would allow a more efficient manufacturing process and thus lower the customer’s cost. These parts were created using soft tooling and come in various interesting shapes.

Precision dunnage

Challenge: Create precisely fabricated dunnage parts cost effectively.

Solution: These parts needed precision in both the part and the tooling. To help reduce tooling costs and time, UI created prototypes using our in-house 3D printer – which allows us to produce a working model in a day.

Idler rollers

Challenge: Create lightweight idler rollers for industrial application.

Solution: Used in the glass industry, these idler rollers needed to meet the customer’s exacting tolerances while also remaining lightweight and somewhat crushable. UI worked with the customer to find the right durometer that met the needs of the application – while remaining within the customer’s price point.

Urethane bumpers

Challenge: Create very small urethane bumpers with uniform composition.

Solution: A customer asked if we could make these urethane bumpers. The challenge in creating these very small parts was keeping the composition exactly the same throughout each individual part. These parts were created using our compression molding process.

Encapsulated, replaceable battery pack

Challenge:The final design needed to achieve four functional requirements: 1) The battery needed to be encapsulated; 2) The battery, wiring and connector needed to be positively located within tight tolerances; 3) It had to be easy for the end user to handle and replace; 4) The ongoing supply chain process needed to be simple and efficient for our customer.

Solution: UI worked with the customer to provide an appropriate urethane blend that wouldn’t harm the battery nor degrade the charge during casting. We then developed a mold and casting process to suspend the battery pack while over molding with urethane. In addition, the electrical connector and associated wiring needed to be held in a fixed position within tight tolerances. UI provides multiple quality inspections before, during and after manufacturing to ensure the end-user receives a functional product and 100% satisfaction.

Urethane check valve with steel ball

Challenge: The customer needed to create a urethane check valve (or ball) for use in a wastewater treatment facility. To ensure the urethane ball had enough weight to sink and cover an opening, a steel ball had to be suspended dead center.

Solution: In order to precisely suspend the steel ball within the urethane, UI had to develop custom tooling. If the steel ball wasn’t centered correctly, the check valve would be unbalanced and would fall to that side repeatedly inside the wastewater tank. Over time, the urethane would then wear out. Centering the steel ball helps ensure the urethane check valve wears longer. (Sound complicated? This was one of our more challenging requests.)

Urethane cradles for collectors’ display cases

Challenge: Cost effectively create parts, of various sizes, that would hold collectors’ prized items.

Solution: UI and the customer discussed the potential future product line and the anticipated various sized items that would need manufacturing. The parts, while varying in shape, needed to fit a standard rack that fit inside the display case. UI designed tooling using modular components, which allowed us to change only a section of the mold to make the multiple items. You can see another part made from this “modular” tooling concept in the photo to the right.

Urethane cradles for collectors’ display cases

Challenge: A second photo of the types of various sized parts made to hold collectors’ prized items using “modular” tooling.

Solution: Since only one section of the mold was part specific, the other mold components were used for multiple items. This concept saved the customer tooling dollars and time to market.

Fiber optic cabling part

Challenge: Create curved parts that sit inside a fiber optic spool.

Solution: These small parts feature a curved edge that guides a fiber optic line on and off a spool wheel. Because the cable is quite abrasive, urethane was chosen due to its abrasion resistance.

No-Crush Wheel with Metal Core, Bearings

Challenge: Create a no-crush wheel with bearing that would roll with exacting precision.

Solution: To achieve the precision the customer required, UI created this no-crush wheel, which features a machined aluminum core and two bearings. The urethane was cast around the core and bearings. Short vanes also ensure the wheel has the right amount of give.

Miniature Covered Bearing

Challenge: Create a very small covered bearing — without crushing the bearing.

Solution: One of our more challenging projects, UI created the cover for this miniature bearing by casting it using a one-step process versus the standard two-step process. The result is a covered bearing that meets the client’s tight tolerances.

Grooved Covered Bearing

Challenge: Create a covered bearing with a groove in the outside diameter to accommodate a belt.

Solution: Once the urethane cover was cast around the bearing, UI then machined in the groove as a secondary operation. Due to the application use (this bearing would accommodate a belt), tolerances were quite tight.