We go the extra mile – without you having to ask

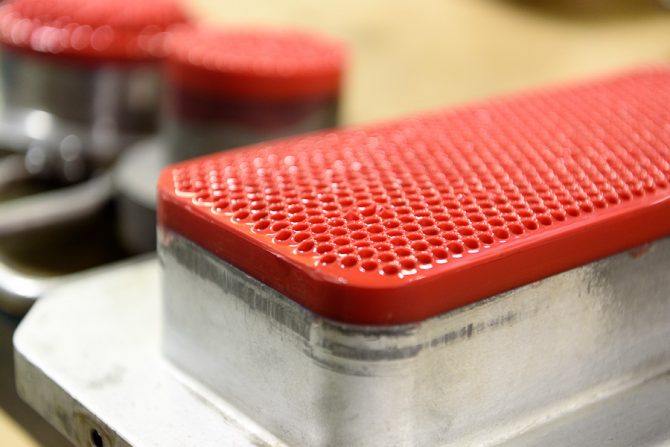

One of the many services we provide is recovering rollers. When these parts come in, the urethane is beat up, dirty, and nicked. It would be easy to simply strip off the urethane, recover them, and send them back out the door.

But, nope, we don’t do that. Instead, we strip off the urethane and then check the insert and journal for damage. We test for runout or other issues and if we find anything, we call you.

If you approve, we then make any needed repairs. Once the insert is repaired and any “wobble” fixed, it’s recovered according to your specifications.

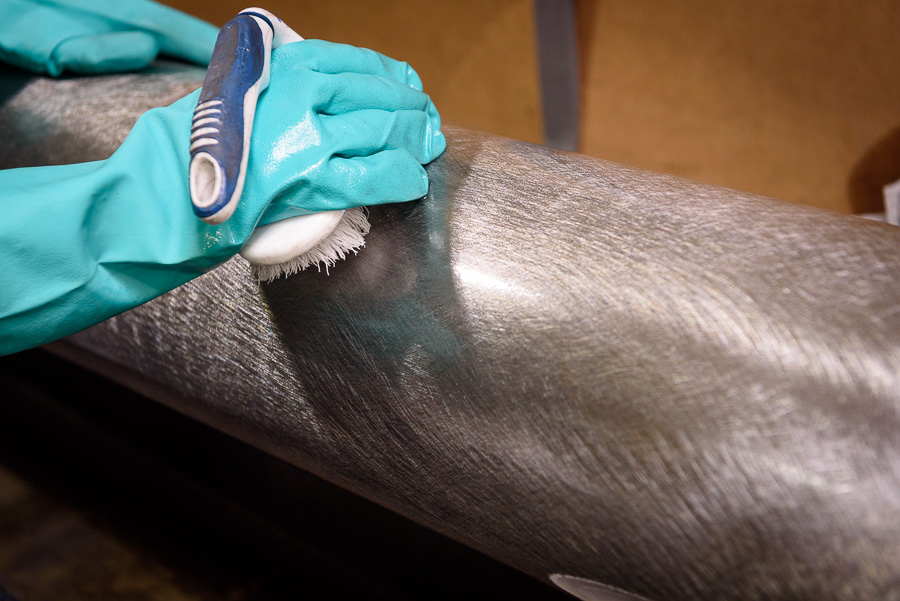

Once cured, all urethane rollers are carefully ground to a silky smooth finish – with durometer and circumference checked before, during, and after.

But we don’t stop there. Using our proprietary process, we then package your rollers so that the protective shipping paper we wrap them in doesn’t stick to the urethane.

When they arrive at your facility, your rollers are like new and ready to use.

And that’s just one way of the many ways we go the extra mile for you.

Learn More

How the ISO 9001 Process Changed UI’s Culture

Three examples of how Urethane Innovators practices continuous improvement.

Challenges Solved

We've built a reputation for tackling tough manufacturing and industrial challenges using urethane, silicone and plastics.