People calling Urethane Innovators for the first time are often surprised to learn we can recover their existing urethane rollers and wheels.

Our recovering service includes all types of rollers and wheels, from no crush wheels and drive wheels to very large industrial rollers used on manufacturing lines or within equipment.

To give an idea of how we can save you a tremendous amount of money, and keep our landfills free of industrial waste, what follows are two “before and after” examples of the types of jobs we do pretty much every day.

Example #1: 16.5″ OD x 4″ wheels with steel core and bearings

The first set of wheels (Figure 1) were in pretty bad shape upon arrival at UI. The urethane covers were cracked and the urethane was beginning to delaminate. The wheels also no longer met spec due to being worn down from use.

In addition to the steel core, these wheels came with two bearings and a spacer. In order to replace the urethane covers, UI had to remove both the bearings and the spacer.

After a brief consultation, the customer elected to re-install them once they received the recovered wheels versus having UI do it. We cleaned them up and included them with the recovered wheels.

Process for recovering:

- Strip the urethane cover from the steel core.

- Check the core for cracks or damage. (In case of damage or excessive wear, UI notifies the customer; we can also replace a damaged core if necessary at our in-house machine shop.)

- Confirm durometer and other technical specifications with the customer.

- Clean the cores and prepare them for the new urethane covers.

- Cast the new urethane covers and cure.

- Machine or grind the new covers to spec.

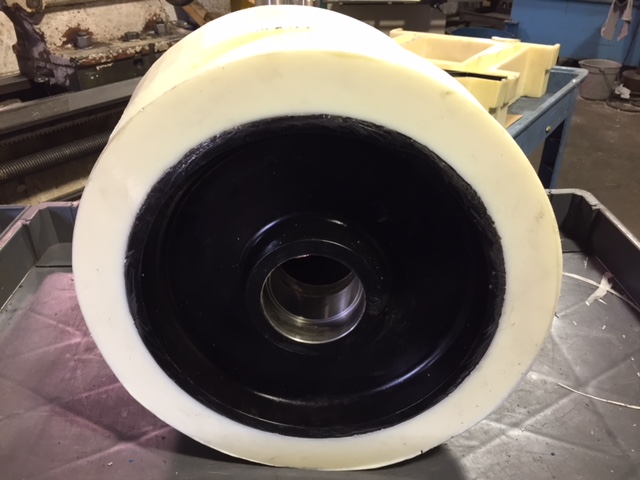

Figure 2 shows the recovered wheel, which will be ground and cleaned before shipping.

Example #2: 16″ OD x 7″ wheels with steel core

From the same customer, this second set of wheels also arrived in bad shape. (The wheels are used in a heavy industrial application, which subjects them to a lot of abuse.)

As you can see, while the cores were in good shape, the urethane covers definitely were not! (Figure 3)

UI followed the same process for recovering as above for these wheels — minus the removal of bearings. Figure 4 shows the new recovered core for one of the wheels.

The one big benefit for the customer in recovering these wheels is cost. The cores were made in France by an OEM. Ordering new ones would be quite costly due to shipping.

By having UI recover the cores, the customer saved money; they were also able to choose a harder durometer to help the urethane covers stand up to the constant abuse of the application.

If you have wheels or rollers that need replacing, don’t toss them in the landfill. Call UI instead. We can consult with you to see if they’re good candidates for recovering — nine times out of ten, they are.