Urethane Innovators manufactures all types and sizes of urethane no-crush rollers and wheels suited to your industrial or manufacturing application.

Our expertise includes determining the best wheel geometry in order to provide cushioning, shock absorption, and pressure consistency, and to move product along the line without damaging or marking it.

The constant flexing produced by the no-crush design minimizes fatigue and premature failure. (See our Urethane No-Crush Wheel FAQ page for additional info.)

Urethane no-crush wheels are ideal for use in manufacturing and industrial applications, including:

- Corrugated cardboard and textile manufacturing

- Printing

- Product labeling

- Material handling

We can create unique vane patterns to ensure the wheel “crushes” (or flexes) to your specification. By varying the durometer along with the frequency and geometry of the vanes, the possibilities are almost endless.

This no-crush wheel is fairly strong. Notice the amount of urethane in each vane and the number of vanes. This no-crush wheel also includes a keyway in the inner diameter.

No-crush wheels of various durometers showing vane angles and design types.

No crush capper wheels created for an industrial bottling application.

Inserts, Cores and Bearings

Applications where the material is to be driven or pulled, or is uneven in nature, often require an insert or core.

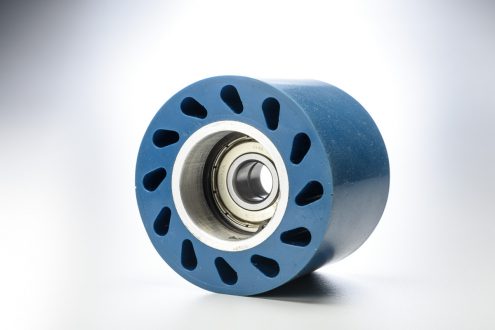

For idler applications, zero crush wheels can have a pocket cast at the center into which a bearing is pressed by hand. If the bearing wears out, you can easily replace it.

Urethane Innovators can make no-crush wheels using cores and inserts manufactured in our in-house machine shop or with bearings you supply.

These no-crush rollers have a set screw on the opposite end of the roller (not shown). The screw makes the roller lock in place on the shaft and thus becomes a drive roller.

This no-crush roller utilizes a machined aluminum core with bearings slipped into place, held there by a set of retaining rings. This is another roller with less crushability – again, the more urethane in the vanes, the less the roller can deflect.

A medium durometer wheel with a bearing pressed in the center; this is a good example of an easy way to make an idler wheel with outstanding long life.

Urethane in Action

Request a Quote