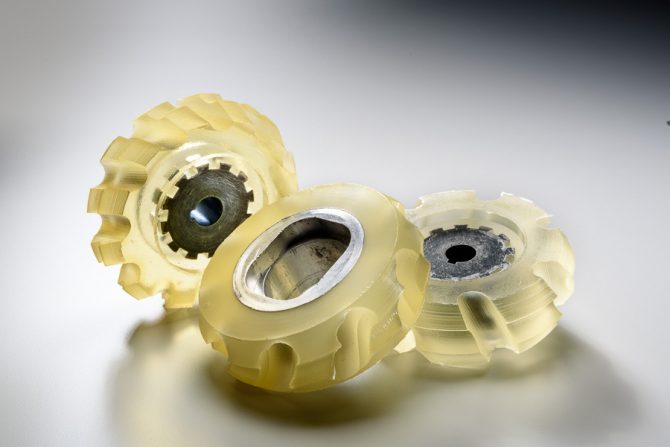

Made-to-spec urethane wheels for tough industrial applications

Whether you need a urethane cast wheel for a food or pharmaceutical application or you need ideas for reducing production costs without sacrificing part quality, Urethane Innovators can help. All work is performed in-house at our New Bern facility.

Our expertise includes finding the best solutions to tough application challenges – such as developing the concave radius wheel pictured.

We manufacture all types of custom urethane wheels

- Idler wheels

- Drive wheels

- Concave radius wheels

- Urethane covered bearings

- Dual durometer wheels

- Automated Guided Vehicle (AGV) Stacker wheels

We meet your unique application challenges

- FDA Approvable urethane for food or pharmaceutical applications

- Custom urethane blends for durometer, temperature, environmental and chemical compatibility

- Additives to enhance specific properties: friction inhibitors, wear extenders, UV absorption, and static dissipative

- Dual durometer: An excellent money-saving option to aluminum or steel in the right application

- Volume production: from 50 pieces to 10,000

We can make (or repair) your cores, too!

- In-house CNC machine shop includes welding and brazing capabilities

- Aluminum, alloy and stainless steel precision machining to tight tolerances

- Fast turnaround that meets deadlines

For applications where the load is light, dual durometer idler wheels make a cost-effective alternative to wheels with metal cores or hubs.

Various wheel shapes, with differing cores and very tight tolerances, created using FDA approvable urethane.

Used in the glass industry, these idler wheels meet the customer’s exacting tolerances while also remaining lightweight and somewhat crushable.

This urethane wheel features three layers and two durometers of urethane: an aluminum core, a hard urethane inner hub (yellow), and a softer outer hub. The aluminum core, created in-house by UI, provides stability, while the inner yellow hub helps reduce weight and material costs.

Using the right additives at precise times during the mixing process is the secret to creating transparent urethane. Made of a medium-soft urethane, this wheel is used to hold down and help move wood through a CNC machine.

The green covered bearing is an example of two bearings covered by a very hard durometer urethane; the red is an example of one bearing covered with equally hard urethane. Each part has been ground to a precise outer diameter.