Superior dimensional accuracy and precision

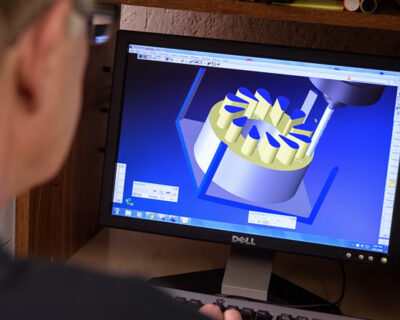

In addition to open molding and spin-casting urethane parts, Urethane Innovators often turns to compression molding technology to produce parts with intricate details and tight tolerances. This makes it an ideal solution for applications where precision is critical and the durometer is low, as it allows for greater control over the final shape and density of the product, ensuring that every product meets the precise specifications required.

Achieve shapes not obtainable with open urethane casting

Compression molding involves pouring urethane or silicone into an open mold, which is then sealed and placed under great heat and pressure. The pressure of the closed mold forces the casting material to fill all areas of the mold while dispelling air, resulting in precise tolerances and more intricate details in the finished part, while often being more cost-effective than injection molding.

If you have a tough challenge that’s left you scratching your head, call us. We’ve probably already solved it – and if not, we’ll figure it out.

The benefits of compression molding include:

Compression molding allows for part geometry and configurations not achieved by other casting methods.

Compression molding is ideal for applications with tight tolerances and low durometer.

With compression molding, secondary operations, such as grinding or finishing, are often not needed.

Urethane Innovators is adept at compression molding a wide range of urethanes, rubbers, and silicones.

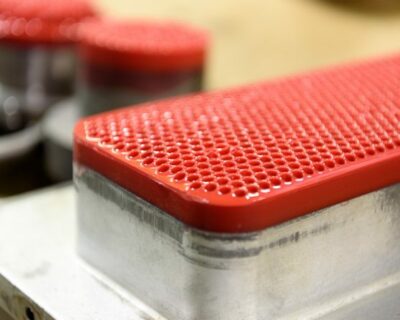

In the following images, you can see how we’ve used compression molding to bond silicone to metal plates supplied by the customer. These plates, used in the manufacturing process, allow the customer to seal food into plastic “fun pack” meals found in the grocery store.

Silicone is specifically used for this application due to its ability to withstand the high temperatures of the customer’s manufacturing process. Urethanes are used when higher abrasion resistance, impact resistance or a wider variety of hardness is required.