We make all types: Idler Rollers, Drive Rollers, Industrial Rollers, Feed Rollers

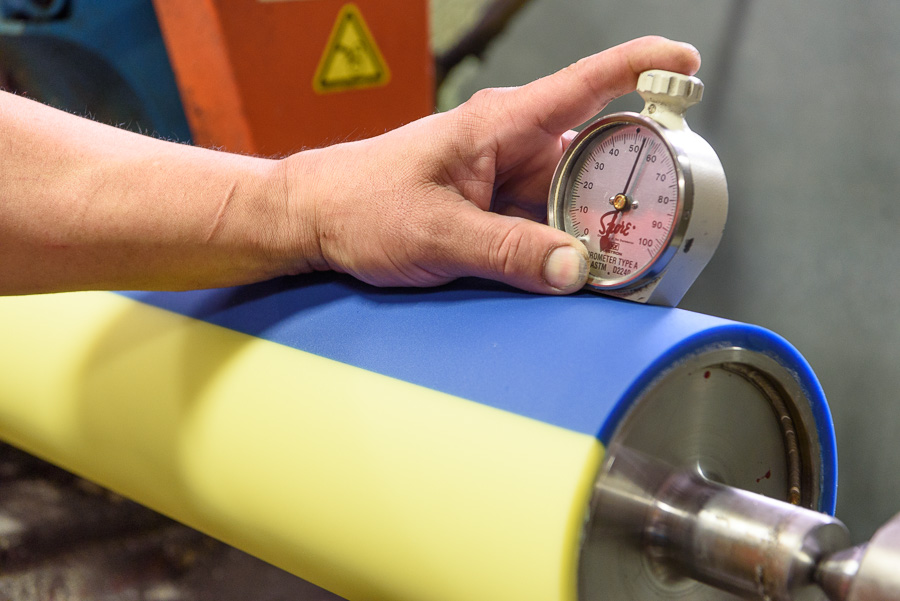

Our expertise is finding solutions to tough application challenges — such as developing the two-tone roller pictured to the left.

This customer needed a roller that provided a visual clue to their employees when the rollers were in operation, to enhance their operational safety. We developed a method to pour the urethane in two colors so that it would be obvious when the roller was spinning without a physical check.

Because we oversee all aspects of production in-house, from engineering and tooling, to machining and finishing — you’re assured of shorter lead times and highest quality.

We manufacture all types of custom urethane rollers

- Drive and idler rollers

- V-Groove and U-Groove rollers

- Transfer, feed and nip rollers

- Soft-touch rollers

- Mini-rollers to large industrial rollers

We meet your unique application challenges

- FDA Approvable urethane for food applications

- Custom urethane blends for durometer, temperature, and chemical compatibility

- Additives to enhance specific properties: friction inhibitors, wear extenders, UV absorption, and static dissipative

We can replace your worn urethane covers, too!

Restore your existing urethane roller to “like new” at a fraction of its replacement cost. Our in-house machine shop and engineering department can work with you to manufacture new covers, correct for journal runout, and precisely grind your urethane roller cover to meet your specifications.

The steel cores and molds for the outer urethane covers were made in-house. The natural urethane roller on the left is 10” long. The blue roller, at 3” long, was especially challenging due to the tight tolerances.

This unique dual roller with aluminum core was designed for a material handling application. By creating a custom aluminum core and utilizing our precision grinding capabilities, UI was able to save cost and production time, leading to better value and lead times for our customer.

A UI craftsman carefully grinds a super soft urethane roller used for staining applications in the flooring industry.

Request a Quote