Responsible for Procurement & Logistics, Jim O’Marra makes sure we don’t run out of items that can bring production to a screeching halt. These items include everything from buckets and raw materials . . . to coffee.

“You really don’t want to run out of coffee around here,” he says. “No one can start the day properly without it.”

Jim came to UI in 202 as Materials Manager after relocating from the Raleigh area. With 20+ years of experience in logistics, manufacturing, and customer service it did not take long for him to get his feet on the ground, and his contributions led to his quick promotion to Logistics and Procurement Manager.

In that role, Jim is responsible for all of UI’s purchasing needs, but equally important is the role he plays in ensuring our shipments are packed and shipped with precision and care. We sat down with Jim recently to get his thoughts on this process.

CM: As logistics manager for custom manufactured and sometimes extra-large or oddly shaped parts, I’m sure there are challenges to receiving/shipping. What has been the biggest challenge?

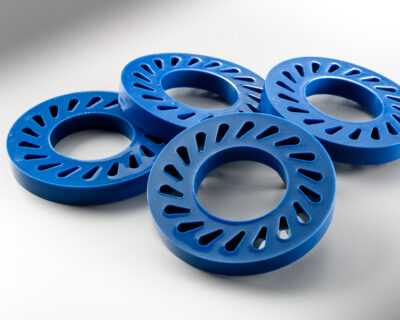

JPO: Because of the breadth of the custom products we make—from tiny 2” no-crush wheels to covered rollers that may be almost 8 feet long—we have to be equally “custom” when it comes to packaging. For instance, we may build custom crates and oversized pallets for the larger rollers that we ship. We tackle these challenges with the same “can-do” attitude and ingenuity that we use to develop unique parts that meet our customer’s needs

CM: “Many of the parts UI ships require special handling. How do you prevent breakage or shipments arriving at the destination in broken or crushed boxes?”

JPO: If a package is ready to ship and it contains loose items for air or ground shipment via UPS or FedEx, we add enough bubble wrap, paper, or foam to prevent the items from moving in transit. This also helps with keeping the integrity of the box intact.

Our larger items ship with “Less-Than-Truckload” (“LTL”) freight carriers (where the pallets are handled through multiple distribution centers and on multiple trucks), all packages are placed in the center of the skid free from any overhang, banded down, and then wrapped with stretch wrap to prevent the products on the skid from moving in transit. All packages get properly labeled as needed regarding “Heavy Package” or “Do Not Stack”.

CM: Over the years, how has what you’ve learned about shipping custom parts translated to saving money for UI customers?

JPO: There is only one true way of saving customers money on custom part shipments and that is by running freight quotes from multiple sources such as Southeastern Freight, XPO, or Estes, etc…when the freight terms have been setup as Pre Pay & Add. We always choose the cheaper option if there is no specified ETD.

CM: How do you organize and prioritize so many shipments?

JPO: We ship products out daily through UPS and LTL carriers. We have areas set up in the shipping department for small outbound shipments as well as large. These areas are kept separate to avoid any type of confusion or mishandling.

What dictates the priority of shipments are customers’ due dates—if we have an overabundance of shipments ready to ship out on the same day, we make sure the ones that are due first get ship first.

CM: Last question, which factors do you consider when determining shipment methods?

DJY: Several different factors go into the process of determining shipping methods for a customer’s order:

- The size of the shipment. If the weight is under 150 lbs, that’s usually a UPS shipment; if it’s over 150 lbs, then it’s an LTL carrier.

- Customer’s preferred method. The saying “The customer is always right” definitely applies here. We ship orders however the customer requests–UPS, LTL, local pickup etc.

- Shipping Costs. Most customers don’t want to pay a lot for shipping if it isn’t necessary. We always try to provide our customers with all the options when it comes to shipping their order. They may say it doesn’t matter how long it takes to get here, just do it at the lowest possible cost.

- Transit time. But then there are some customers that have to have their parts by a certain date and cost isn’t a factor. That means sometimes it’s better to go with a better transit time than a better cost.

Shipping will always play a part in our daily activity, and now we have so many options. At one time, the post office and UPS were the main mailing/shipping options; now there’s FedEx, DHL, and so many others. The only thing we can’t do at the moment is “get it there yesterday,” but we will always do what we can to meet our customers’ needs.