Frequently Asked Questions about UI and Urethane in General

How do I place an order?

Please contact Jim O’Marra jomarra@urethaneusa.com or Trish Lewis plewis@urethaneusa.com, or feel free to call 800-545-2630 or 252-637-7110 and ask for our sales team.

New customers interested in a quote can also see our RFQ page for the information we need from you; you can call, email, or submit the RFQ form.

Depending on the application, the quote turn-around time is 24 hours to one week.

I have a custom application? Is this something you can help me with?

Absolutely! If you haven’t already, take a look at our Challenges Solved page, which will give you a good overview of the types of things we’ve tackled.

To help meet your application needs, we first talk to you about what you’re trying to solve. We then customize our formulations with the addition of additives. Typical requests include:

- FDA approvable

- Load bearing capacity

- Abrasion resistance

- Impact absorption

- Tear strength

- Friction limiters

- Anti-static

- UV inhibitors

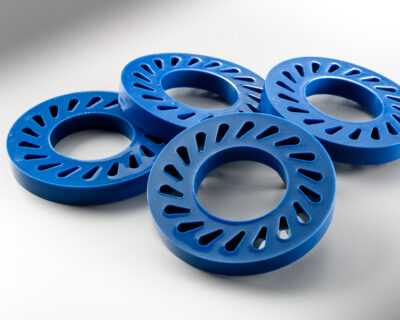

We can also tailor the color of your urethane product to suit your need and application. Many of our customers use color to color-code similar parts, to improve safety (e.g. blaze orange), or to control items manufactured in different years.

Can you manufacture product over a specific time period and ship at pre-set dates?

You bet! We refer to these types of orders as “blanket orders.” You tell us how many and when for the coming year, and we’ll make sure you receive them at your selected dates. By setting up your order this way, you help reduce your manufacturing and other related costs.

Why should I consider urethane for my application?

Urethane is one of the most durable and versatile materials available. Raw urethane is processed in the liquid state and then mixed, metered, and dispensed precisely by machine. Color and additives are often added to the mixing process – which allows us to customize a formulation to suit your application.

The blended liquids are then poured into molds and cured. Unlike plastics and rubber, urethane can be molded into very large parts with thick cross-sections.

How does urethane differ from silicone rubber or plastic?

Solid urethanes have higher load bearing capacity than other rubbers, and higher impact resistance and resilience than plastics. Solid urethanes have deflection and recovery capabilities unlike any other plastic or metal. Urethanes behave like incompressible hydraulic fluid; when under load they don’t change volume.

Urethane can be deformed without breaking and recovers quickly after repeated deformation. Desired stress-strain properties can be obtained by compound blending; stress-strain characteristics aren’t linear, so urethanes become stiffer with greater deflection and velocity of impact.

We can help you determine deflection based on design, material selection, and load. Our engineering staff will work with you during development if necessary.

Can urethanes stand up to environmental elements or abrasion?

Yes! Urethanes have resistance to oil, water, weather, ozone, oxidation, and many chemicals. Some are even radiation, fungus and bacterial resistant.

Urethanes have high tensile and tear strength compared to other types of rubbers. Urethanes have excellent abrasion resistance and outwear metals, plastics, and other rubbers 8:1 or more. They also have excellent retention of properties at very low temperatures as well as temperatures up to 220° F – higher with some compounds.

Can we bond urethane to other materials?

Yes! Urethane is often used where shock absorption from vibration is required, such as shipping, automotive, and aerospace applications.

Because of its versatility, urethane can be chemically bonded to other materials, including other urethanes, metals, and plastics.