People are often surprised to hear we can recover worn rollers. By “recovering,” we mean we can replace the worn urethane or rubber cover that’s chemically bonded to a metal core.

Sometimes this process is referred to as “lagging” or “vulcanizing” (although strictly speaking, vulcanizing refers to hardening a rubber cover).

Recovering worn roller covers is a specialty here at Urethane Innovators, and in fact, we can recover just about any roller you send us:

- Most lengths and diameters

- Durometer – including super soft

- Any OEM make or model

- Application type: Processing, manufacturing, material handling, coating/staining

- Specialty: two-color, dual durometer, mini

Once customers realize we can recover their rollers, they often follow up with a slew of other questions.

Do you remove the urethane cover from the core and replace it?

It depends on the state of the roller and your equipment’s adjustability. When rollers come in for repair, the urethane covering may be pitted and banged up. Depending on the type of roller and the finish requirements, we may be able to regrind the urethane cover – saving you considerable cost and lead-time.

In these “before” and “after” photos, you can see a roller sent in for recovering. For this particular roller, we couldn’t regrind it; instead, we replaced the entire urethane cover. As an aside, we’re experts at making these two-color rollers. Because they’re two-color, the customer can see they’re moving when the conveyor is running at high speeds.

What is regrinding?

It’s a process where we use either our precision grinding equipment, or machine tools, to smooth out the urethane surface.

However, if the cover has cuts or gouges deeper than the minimum finished diameter, or if the cover is delaminated, mushy, deformed, or stretched out of shape, then we need to strip it and make a new cover.

What if the journal or core is damaged? Can you fix it?

Yes we can! We check rollers for broken bolts and any needed journal repairs – and won’t do any repair without approval from you.

We make all journal repairs in-house in our machine shop. Depending on the state and construction of the journal, we’re able to do the following:

- Use heat or force to straighten

- Build up worn areas by welding and then machine to correct dimensions and alignment

We can replace the entire core if necessary due to breakage or other issues.

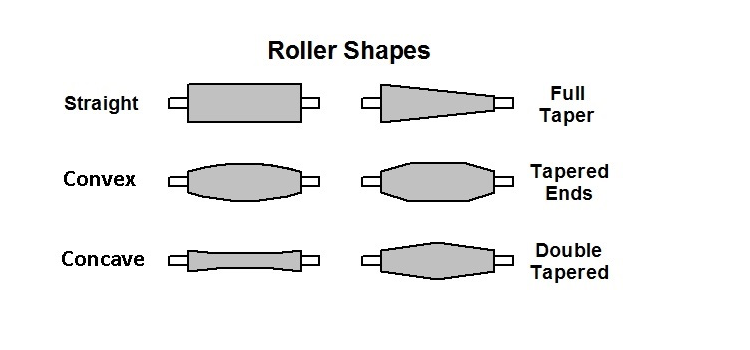

Can you grind our roller cover even if it’s an odd shape?

Yes, in fact, we specialize in all sorts of shapes and sizes of rollers. Our capabilities include:

- Straight Grind

- Convex Crown

- Concave Crown

- Straight Taper

- Straight Taper with Center Flat

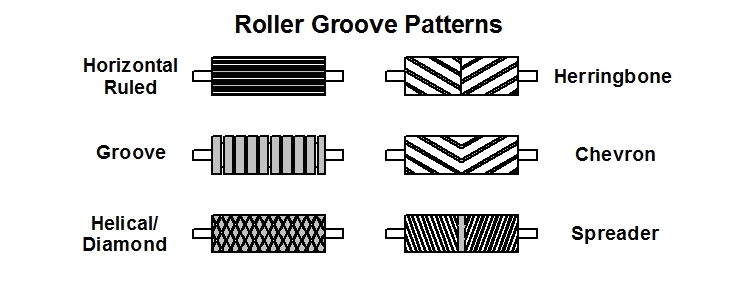

Our rollers have special grooves on them. Can you replicate those?

You bet! We can handle radial and horizontal grooves as well as specialty grooving:

- Chevron

- Spiral

- Cross-Hatch / Diamond

We have multiple rollers made by a manufacturer and need to replace one of them. Can you make a new one to match our existing rollers?

Yes! We can reverse engineer an existing roller or create one using your specifications. Your new roller will meet or exceed your performance goals.

This is all great information! How do we go about getting our rollers recovered by you?

That’s easy! Use our Contact info below to call, email, or start an RFQ. ???? ???? ????

And, if you need urethane-covered rollers manufactured from scratch for your application, we can do that, too! Just give us a holler.