How we make the cores for your custom urethane wheels

Over the course of a year, we make a whole bunch of wheels . . . big wheels, little wheels, hard durometer wheels, soft durometer wheels – and wheels of many colors (see our photos at the bottom of the page).

What many of these wheels (also called rollers by some) have in common is a stainless steel, aluminum or steel core, insert or hub. And, what many people don’t know is that we make many of the cores or inserts in-house.

Precision starts in our CNC machine center

Our founder, Bob Liland, doesn’t like inefficiency or shoddy workmanship. After one too many times of having a core or insert job get delayed and/or not meeting specs because he sent it to an outside machine shop, Bob did what he always does: he bought the technology (that’s retired Navy for you).

In this case, he purchased a CNC machine and then had one of our craftsmen trained to use it.

Today, our machine center, located in the heart of our factory, is equipped with five state-of-the-art CNC machines. It’s here that we make our molds and repair or replace roller journals.

It’s also where we make the cores, inserts and hubs for the thousands of wheels we manufacture each year.

Boring, tapping, keyways, face grooving – no problem!

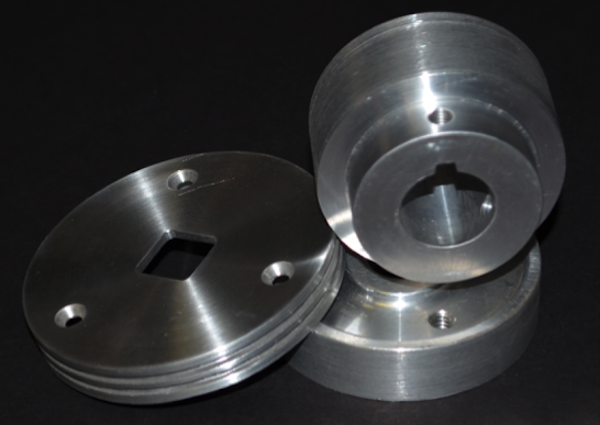

We can make your core, insert or hub to your specification – including machining of most shapes and sizes. The core pictured in Figure 1, for example, has four drilled holes in addition to the center bore and face groove – all machined to exacting tolerance and finish specifications.

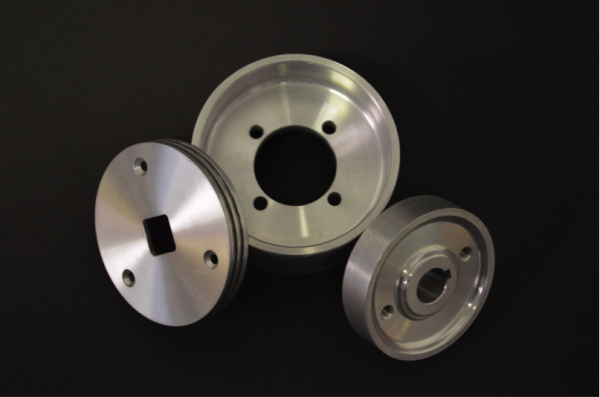

We can also do things such as add grooves to the outer diameter – as you can see in the core pictured to the left in Figure 2.

For this particular core, the customer’s requirements included a mechanical and chemical bond. Typically, we use a chemical to bond the urethane to the metal. In this instance, the urethane sets into the grooves and becomes interlocked with the core – thus a double bond.

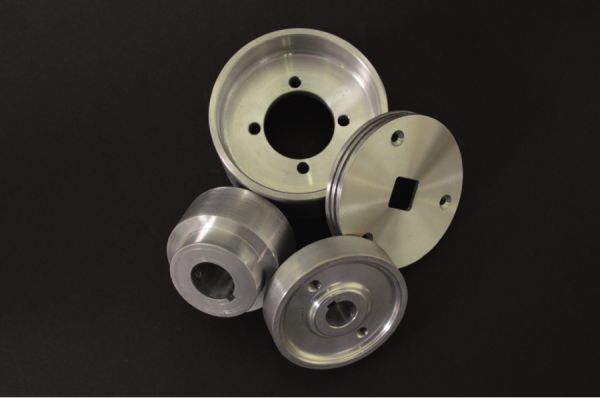

Looking at the four cores in Figure 3, you see a variety of milling processes.

- The bottom two cores are broached to form keyways used to drive the wheel.

- The top and bottom cores have been face grooved to allow for proper installation clearance and to reduce part weight.

- The top core has 4 through holes for installation hardware.

- The right core has a square center ID formed by milling; we can also broach square holes.

- Lastly, we drill and tap holes using live tooling on our CNC turning centers.

Keyways are typically used on drive wheels or rollers. A positive force makes the wheel turn to match up with other parts of the machine. Set screws can also be incorporated to lock the wheel in position to facilitate driving or idling.

By manufacturing cores, inserts and hubs in-house, we deliver three benefits to you:

- Quality – We often catch small errors that other people don’t. If we see a problem with the drawing, we’ll stop all work and contact you to confirm tolerances, specs, etc.

- Fast turnaround – Since we’re not sending things out, we get your project done on your schedule versus waiting on a third-party supplier.

- Lower costs – Since we do the machining in-house, we don’t have other suppliers involved driving up costs. We also carefully review your specifications.

Sometimes a certain material gets spec’d, such as “military” grade aluminum, or as it’s really known as, MIL STD or MIL-Spec Aluminum. We’ll confirm with you if a MIL-Spec aluminum is actually required or if a more cost-effective grade of aluminum would be acceptable. We’re also happy to suggest design changes that reduce manufacturing steps.

In addition to wheels that need cores, inserts and hubs, we also make no-crush wheels and dual durometer wheels. Whatever type you need, just give us a holler – we’re here to help you!