Urethane is a highly durable and versatile material, widely used in industries such as automotive, manufacturing, material handling, and agriculture. With the right formulation and proper maintenance, urethane components can outperform and outlast materials like steel, aluminum, rubber, and plastic. But what factors influence the longevity of urethane products? Here’s what you need to know.

Factors That Affect Urethane Durability

Material Formulation Matters

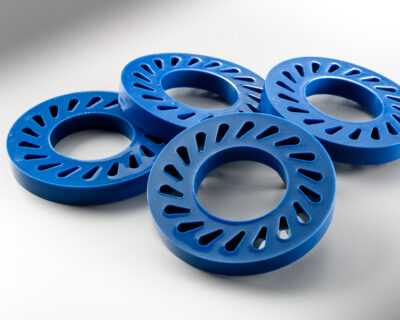

The specific formulation of urethane plays a critical role in its lifespan. At Urethane Innovators, we customize formulations to enhance performance characteristics such as abrasion resistance, load-bearing capacity, and flexibility. With the right formulation, our urethane can outlast steel and aluminum in demanding applications.

Depending on its formulation, urethane is also resistant to oil, water, weather, ozone, oxidation, and many chemicals. Some formulations offer additional resistance to radiation, fungus, and bacteria, making them ideal for extreme environments.

Environmental Conditions Play a Role

While urethane is known for its resilience, exposure to extreme temperatures or humidity, UV radiation, and chemicals can impact its longevity, depending on the type of urethane. Urethane retains its properties across a broad temperature range, from extremely low temperatures up to 220°F—higher with certain compounds. Specialized formulations can further enhance its ability to withstand harsh environmental factors.

Maintenance Extends Lifespan

Routine maintenance can help maximize the durability of urethane components. Regular inspections, cleaning, and prompt repairs of minor damage can prevent premature wear and extend the life of urethane products. Following manufacturer guidelines for proper use and storage also contributes to long-term performance.

How Does Urethane Compare to Other Materials?

When compared to rubber or plastic, urethane offers superior wear resistance, impact absorption, and load-bearing strength. Urethane components outwear metals, plastics, and other rubbers by a ratio of 8:1 or more, reducing replacement costs and downtime in industrial applications. Unlike rubber, which can crack and degrade quickly, or plastic, which may become brittle over time, urethane maintains its structural integrity under heavy loads and repeated impact.

Maximizing the Lifespan of Your Urethane Products

To ensure your urethane components perform at their best for as long as possible, follow these best practices:

- Choose the appropriate urethane formulation for your specific application—different formulations offer differing physical characteristics and varied resistance to moisture, solvents, etc.

- Implement routine maintenance and inspections to identify early signs of wear.

- Work with an experienced urethane manufacturer, like Urethane Innovators, to develop custom solutions tailored to your operational needs.

The lifespan of urethane products is influenced by several factors, but with the right formulation, environmental protections, and maintenance, they can significantly outlast alternative materials. At Urethane Innovators, we specialize in high-quality, custom urethane solutions designed to exceed performance expectations in the most demanding industries.

Looking for urethane products engineered for durability? Request a quote from Urethane Innovators today.