Reduce noise and vibration, improve part longevity

Used primarily in applications that require noise reduction, such as manufacturing or warehouse conveyor lines, urethane covered bearings are just as the name says: bearings with a urethane cover.

The urethane acts as protective cover for the bearings and reduces the noise and vibration associated with bearings moving at high speed — while allowing the inner diameter (ID) of the bearing to spin freely of the outer diameter (OD). The urethane cover also minimizes wear and tear on the bearings — as well as protecting machinery.

Manufacturing urethane covered bearings: it’s all in the casting

The secret to smooth rolling covered bearings starts with the mold, which has to be precisely machined to ensure the urethane doesn’t leak past the bearing seal during the casting process.

The non-leaking aspect is actually more challenging than you think. Since bearings come packed in grease, when the grease gets hot, as it does during the casting process, it liquefies – which means it has a tendency to want to leak outside the bearing seal.

If the grease leaks out, the urethane won’t stick to the bearing. If the urethane leaks into the bearing, the bearing won’t spin properly – and thus is rendered useless.

Over the years, UI has developed several ways to combat this problem through mold design, process modification, and just plain ol’ ingenuity. We’ve learned how to seal the bearing properly in the mold to prevent urethane leaking into the bearing.

We’ve also modified our casting process specifically for covered bearings to make sure the grease in the bearing doesn’t get too hot and leak out.

Examples of specialized urethane covered bearings

Grooved Covered Bearing

For this modification, the customer wanted a groove machined into the bearing as a secondary operation (machining performed at our in-house machine shop). And, since a belt runs on the covered bearing, tolerances were quite tight.

Double bearing cast in place

To increase load capacities, customers often ask that we cover two bearings – and to make the job more challenging, they’ll request the bearings not touch one another.

This next photo shows two bearings cast in place. For this application, the double bearings help evenly distribute a heavy load – as a single bearing wouldn’t be able to handle it. The covered bearings last much longer – which helps the customer reduce parts costs.

A double bearing configuration works well when significant side-loading is an issue. A single bearing takes the brunt of the load and thus is prone to failure; the double bearing just laughs and keeps right on rolling.

Machined radius

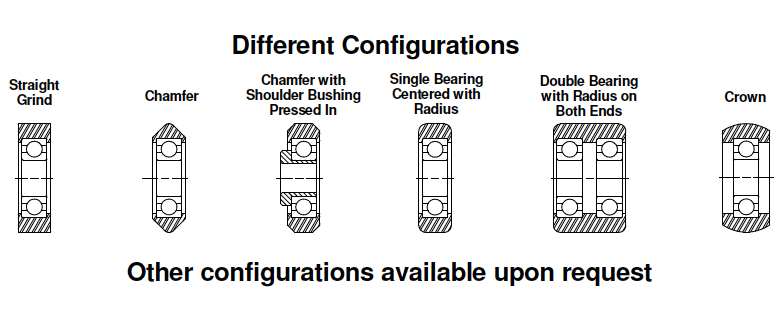

Most urethane covered bearings have a flat face, but sometimes, a customer will want a machined face, a radius, groove or some other feature. These features allow the covered bearing to serve a multitude of purposes.

By looking at the profile options in the photo, you can easily imagine how one of our covered bearings might help you solve a problem.

If you need a specific feature in the profile of your covered bearing – or a name or part number — let us know! As you can see in the diagram, we can handle most any type of configuration.

And, within each configuration, we can do the shoulder bushing, the OD profiles or double bearings.

Miniature Covered Bearings

For this application challenge, the main concern was ensuring the miniature bearings weren’t crushed during the casting process. We also knew it would be good if we could cast the entire part in one step versus two – which is what we did.

In addition to the modifications listed here, we can also do a whole lot more, such as:

- Including any type of information on the covered bearing, such as part ID number or company name

- Creating a color code system based on durometer for easy identification – especially useful if you have the same bearing design serving multiple uses

- Making the urethane cover to any size or specification

- Performing secondary machining operations as requested

We can also supply bearings to your specification or you can send us your new bearings to cover.