Testing and feedback make all the difference

We frequently work with customers who have a new industrial or commercial application. They know what they need (e.g. “we need a 22” diameter wheel that has some flex to it but also needs to carry some weight”), but they’re not quite sure of all the particulars, such as durometer or material.

That’s where UI comes in. Using customer supplied drawings and answers to the questions we ask, we create working prototypes that allow customers to test their concepts and then supply us with feedback. Using the feedback, we then make modifications until the customer is satisfied.

Because we get so many questions about prototyping and what’s involved, we’ve included a few of the interesting applications we’ve worked on to show how it’s done.

Retrofit Drain Seal

The customer faced the challenge of creating a series of seals that would self-adjust to the pipe size. In addition to being self-adjusting, the drain seals needed to maintain drain flow-rate codes and provide leak-proof protection.

According to the customer, this type of application hadn’t been done before, but would UI be willing to take it on? Oh, and by the way, “we’re six months behind schedule, so we need this yesterday.”

UI’s challenge was to figure out how to turn prototypes around quickly so they could be tested and modified, if necessary (they needed to be modified a few times). Through a determined company-wide effort, and using our 3D rapid prototyping capabilities, UI and the customer’s engineering team fabricated multiple prototypes and proof-of-concept parts in weeks, allowing the customer to perform in-house flow-rate, leak and functional testing in record time.

Normally, we use our 3D printer to produce a master — a likeness of the part from which we can create soft tooling. In this instance, however, using the 3D printer allowed us make prototype molds in a fraction of the time.

Although the molds weren’t 100% perfect dimensionally, they allowed UI to prove the tooling concept, produce parts for the customer to test, and prove out materials — all at the same time (and saving significantly on costs).

The tooling concept, along with the 3D printing capabilities, allowed the customer to run through several iterations of changes before deciding on a final design.

The expedited efforts helped the customer get ahead of schedule, present actual product at their annual industry trade show, and be first-to-market. Read the full case study.

“Puzzle Piece” Belt for an Industrial Machine

A customer needed to create a belt that snapped together in order to hold an idler wheel in place on a machine. It needed to quickly and easily slide together – as well as meet very tight tolerances.

To create this part, UI worked with the customer to test non-silicone mold release on the urethane belt. This test was important, as the right non-silicone release would allow the customer to glue the part together and save significant changeover time by not having to remove the shaft to replace the belt. They would simply cut off the old belt and glue on the new one.

UI also reviewed the customer’s concept drawings and made recommendations for reducing production costs. Once the belt was finalized, we worked with the customer to choose the right type of adhesive to be used in the belt seam. The adhesive chosen needed to be durable, flexible and resistant to strain. It also needed to set up quickly to keep in line with the quick changeover parameters.

Increase roller life from weeks to months by changing durometer

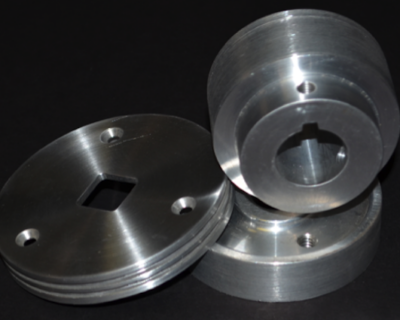

A customer called to ask if we could create a prototype roller in order to test its use on a machine. The new roller would replace a belt.

The prototyping process can involve failure, and in this case, the material the customer initially requested failed big time. Why? The complicating factor with this roller is that the material needed to be FDA compliant for dry food contact. The lower — or softer — the durometer, however, the harder it is to get a durable FDA material at a reasonable cost.

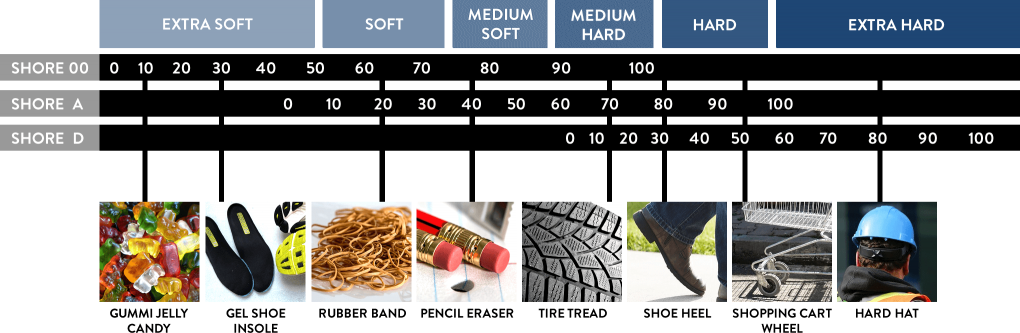

After talking to the customer about the environment in which the roller operated, UI recommended a durometer change – from 30A to 40A – as well as changing the material blend.

What a difference 10 points on the durometer scale can make! The first prototype 30A rollers lasted only a few weeks. The new 40A ones have lasted months.

Have a commercial or industrial concept for which you need a prototype?

If you have an application where you need prototypes to test proof-of-concept, give us a call. You can also

complete our Request for Quote form, which asks you many of the same questions we’ll ask you about application environment, etc. as well as upload a drawing. We’ll be sure to get right back you! Thank you!